Tips to Find the Best Plastic Injection Moulding Manufacturer

Introduction

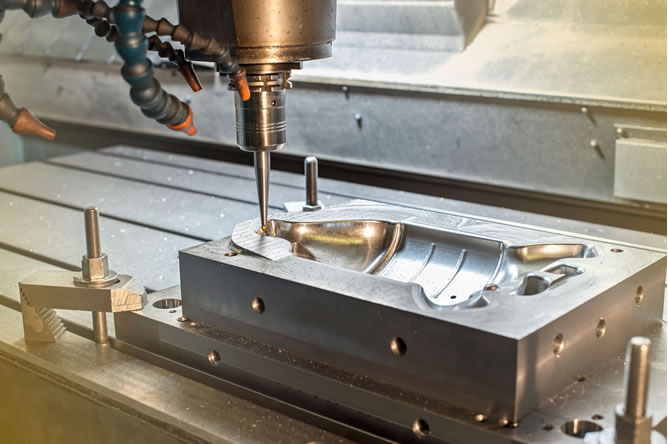

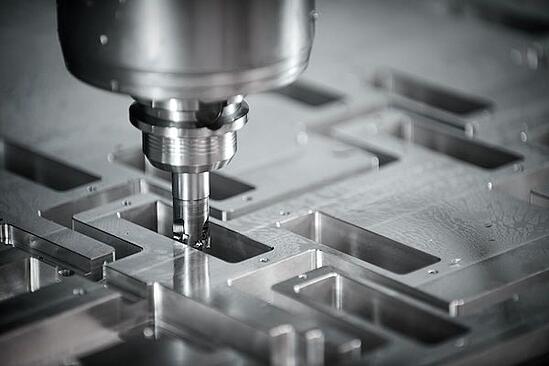

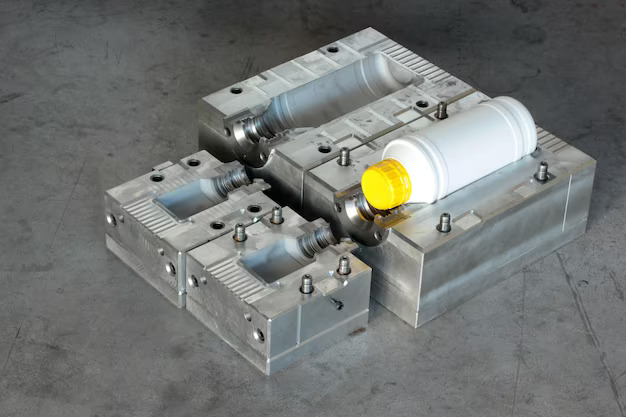

When selecting a plastic injection moulding partner that is most suited for your industry, distinctive goods, and production needs, there are many aspects to take into account because the manufacturing process might be intricate. First and foremost, learning the fundamentals of the plastic moulding procedure is the ideal place to start. In its most basic form, the procedure involves the use of polymers or plastic resins, which, when heated, melted, and injected under high pressure into a certain mold, will result in plastic parts that may be used in the production of goods. Even though the procedure appears simple, many manufacturers want an injection moulder partner who can create extremely complicated parts while also meeting their particular industry needs, specs, end uses, and time and budgetary restraints.

The following are the main aspects that any product maker should take into account when selecting a plastic injection moulding:

Specialization & Capacity for Volume:

It’s crucial to focus your search for an injection moulding firm by taking the volume and scale of your manufacturing requirements into account. Distinct moulders have different areas of specialization. Injection moulders with low to moderate capacity can meet your demand for a production of 10,000 parts or less.

For individuals who are exploring these volume ranges or seeking to develop prototypes for testing, low to moderate-volume productions are fantastic. It is not necessary to produce various applications in big amounts, such as medical devices, aeronautical engineering components, agricultural components, etc. Such orders are suited for a low to moderate-range moulding company.

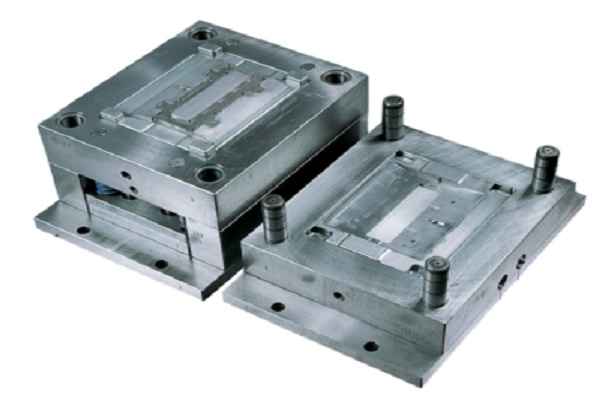

Moulders that specialize in creating bulk volumes (more than 7,50,000 units) should be taken into consideration for parts that require high production volumes. These are typically taken into account for parts made with tiny molds.

Full Spectrum of Services

Regardless of the kind and quantity of plastic parts you require, it’s crucial to take into account a plastic injection moulding business that provides a one-stop production solution.

It is possible to generate the best designs that fit your needs and your budget by working with injection moulding businesses that also offer early-level consultancy, beginning with the part’s design and concept stage.

Think about both the expanded services and technical needs during the manufacturing process when choosing a moulding firm. It is highly advised to select a mold maker who provides a full range of services, including the prototype, part design, mold flow analysis, etc. in addition to the standard services.

A plastic injection moulding firm that offers a one-stop shop will assist you in producing the products you want while meeting your schedule and financial requirements.

Products & Services

The product application should be taken into account when selecting an injection moulding business. When thinking about different manufacturing processes including the design, development, and production, the part’s intended purpose is crucial.

You should be able to get advice from an injection moulding company on the best plastic resin to use for various product applications.

Various plastic resins’ strength, malleability, flexibility, durability, heat resistance, etc. varies. Metals are currently being replaced by plastic in a variety of industries to lighten products and cut costs.

Based on the intended usage of the product and your budget, your chosen moulding firm should be able to advise you on the best plastic resins.

Quality Control

It’s critical that the plastic injection moulding company you choose is well established and has an internal quality assurance team to oversee the process, in addition to factors like technology and standards.

Although this component is frequently disregarded, it is quite important in making sure that you receive the greatest services.

The plastics industry is incredibly cutthroat. Selecting an injection moulding business that can produce products with a guarantee of quality and is dedicated to offering effective services

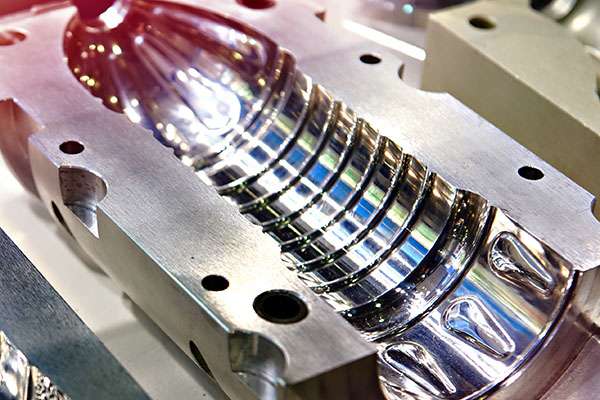

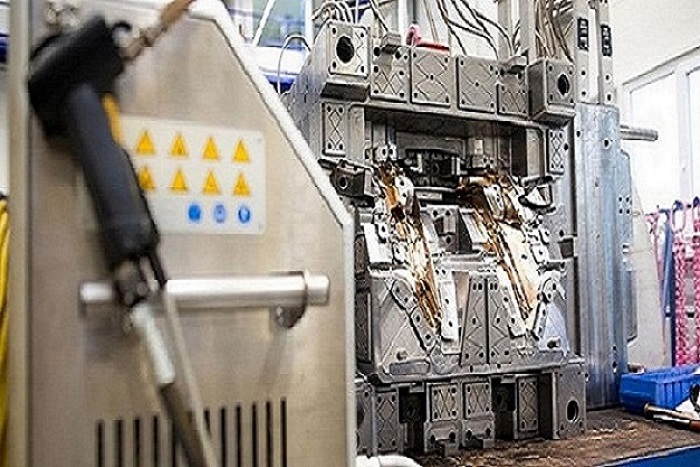

Verify that the injection moulding partner you’ve picked has the best equipment available. Moreover, make sure the business is well-known in the field. It is advised to conduct a brief background check on the evaluations and performance honors received by the moulding company.

Ask them about the software they use for project management, the inspection procedures they employ to verify the components, their mold maintenance programs, etc.

Last but not least, confirm that the company you’ve picked for your plastic injection moulding is ISO certified to ensure that your plastic part moulder satisfies the appropriate quality standards.

Keeping up with time

When making plastic moulded parts, time is a crucial factor to take into account. It can take four to twelve weeks to build a mold.

Therefore, it is crucial that the mold designers take into account a variety of time-consuming processes, such as design modifications, the complexity of the part, and the length of time needed to consult with the designers and engineers.

Additionally, it’s crucial to budget for unforeseen delays like plastic resin shortages and shipment snafus. Early on in the project, it’s crucial to discuss your time limits with the plastic injection moulding business you’ve picked. This will enable you to determine their level of output and provide you with an accurate time estimate.

Additionally, it’s important to carefully negotiate with the injection moulder any plastic components with unique design requirements. It is crucial to let your selected plastic injection moulding firm know what you hope to achieve and the difficulties you face.

Conclusion

It is beneficial to take into account each of the aforementioned elements when selecting a reputable plastic injection moulding business. Selecting a plastic components manufacturer that is aware of your needs will be easier if you conduct thorough planning and research at the project’s conception stage.