Importance of plastic components manufacturer in Automobile & Medical industries

The importance of plastic components cannot be overstated, especially in sectors as critical as automobiles and medical equipment, where a Plastic components manufacturer plays a very important role. These lightweight, durable, and versatile materials have revolutionized automobile and medical industries, enabling innovation, efficiency, and improved performance. The crucial role that plastic components manufacturer play in both the automobile and medical sectors, and let us look into how their contributions are shaping the future of these industries.

Plastic Components in the Automobile Industry:

The automobile industry is interchangeable with innovation and advancement. Plastic components have become an integral part of this field, offering a range of benefits that have transformed the way vehicles are designed, built, and operated.

1. Lightweighting and Fuel Efficiency:

Plastic components, known for their lightweight nature, have allowed automakers to address the critical issue of fuel efficiency. By replacing traditional metal parts with high-strength plastic components, vehicles can shed excess weight, resulting in improved fuel economy and reduced emissions. This not only aligns with environmental regulations but also appeals to consumers seeking more environmentally friendly options.

2. Design Flexibility:

Plastics offer unparalleled design flexibility, allowing automotive designers to experiment with intricate shapes, sizes, and textures that were previously unattainable with metals. This creative freedom not only enhances the visual appeal of vehicles but also contributes to aerodynamics, safety, and overall performance which is why a plastic components manufacturer plays a vital role in the design aspect of the automobile industry.

3. Cost Efficiency:

Plastic components are generally more cost-effective to produce by manufacturer compared to their metal counterparts. The lower production costs can lead to reduced manufacturing expenses, allowing automobile makers to allocate resources to other areas of vehicle development or offer more competitively priced vehicles to consumers.

4. Enhanced Safety:

Plastics have revolutionized vehicle safety by offering energy absorption properties that are crucial during accidents. Bumpers, airbags, and safety belt components are often made from plastic materials designed to absorb and distribute impact forces, minimizing the risk of injury to passengers.

Plastic Components in the Medical Industry:

In the medical field, precision, reliability, and safety are of paramount importance. The integration of plastic components and the role of a plastic components manufacturer has elevated medical devices and equipment to new levels of efficiency, accessibility, and patient care.

1. Sterilization and Hygiene:

Plastic components are often used in medical devices due to their compatibility with various sterilization methods. Their non-reactive nature makes them ideal for ensuring the sterility of medical instruments and equipment, crucial for preventing infections and ensuring patient safety.

2. Biocompatibility:

Many plastic materials used in the medical industry are biocompatible, meaning they are well-tolerated by the human body. This property is essential for implantable devices, prosthetics, and other applications that come into direct contact with bodily tissues.

3. Precision and Customization:

Medical procedures often require devices that are customized to suit individual patient needs. Plastic components can be fabricated by a plastic components manufacturer with high precision, allowing for the creation of intricate medical instruments tailored to specific anatomical requirements.

4. Accessibility and Affordability:

Plastic components have played a key role in balancing access to medical care. They have enabled the development of portable, affordable medical devices that can be used in remote or resource-constrained areas, making healthcare more accessible to a wider population.

The Vital Role of Plastic Components Manufacturers:

The symbiotic relationship between components manufacturer and the automobile and medical industries is instrumental in driving progress. These manufacturers act as the backbone of innovation, producing components that align with the unique demands of each sector.

Research and Development:

Plastic components manufacturer invest significant resources in research and development to create new materials that meet the stringent requirements of the automobile and medical industries. This involves experimenting with materials that are durable, heat-resistant, chemical-resistant, and safe for use in demanding environments.

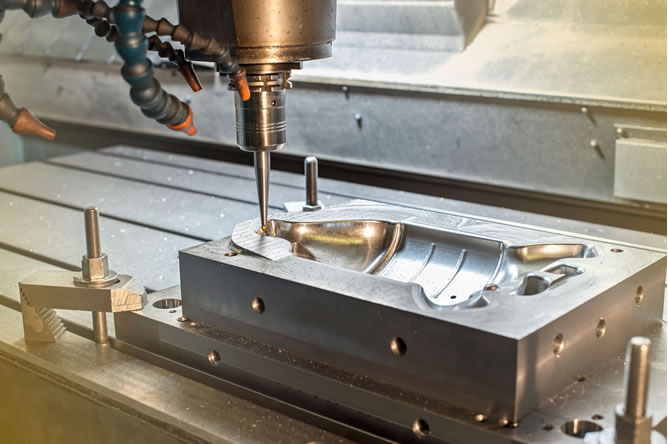

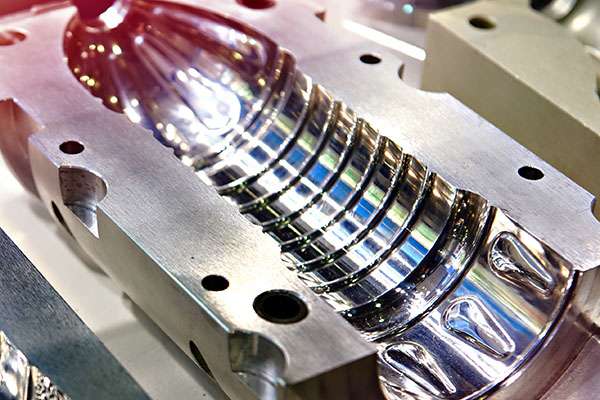

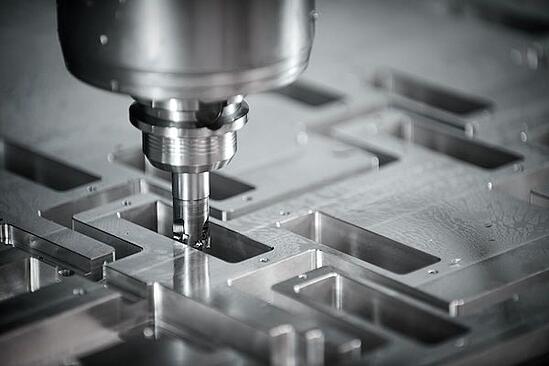

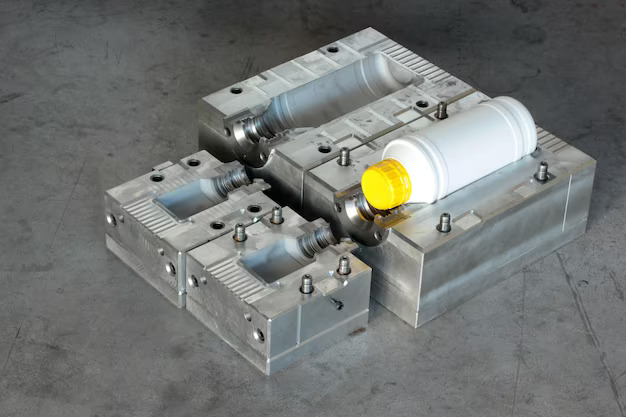

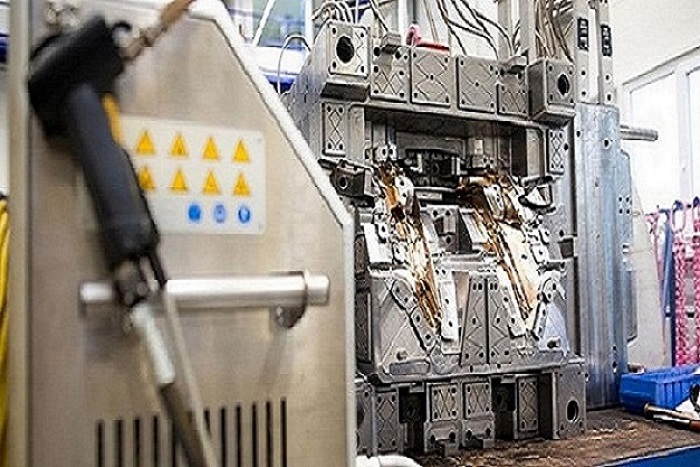

Precision Engineering:

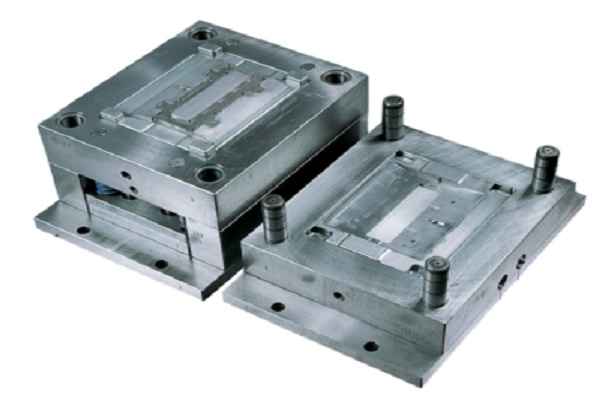

Both the automobile and medical industries require a high degree of precision in component manufacturing. Plastic manufacturers employ advanced technologies such as injection molding and computer-aided design to ensure that each component meets exact specifications, contributing to the safety and reliability of the final product.

Regulatory Compliance:

The automobile and medical sectors are heavily regulated to ensure the safety and well-being of consumers and patients. A plastic components manufacturer plays a pivotal role in adhering to these regulations, producing components that meet industry standards and undergo rigorous testing for quality and performance.

Innovation and Collaboration:

As industries evolve, plastic manufacturers collaborate closely with automakers and medical device manufacturers to innovate and address emerging challenges. Whether it’s developing plastic composites that enhance structural integrity in vehicles or creating antimicrobial plastic coatings for medical devices, these collaborations drive progress and elevate industry standards.

A plastic components manufacturer serve as catalysts for innovation and progress in the automobile and medical industries. Their ability to create lightweight, durable, and versatile components has reshaped the way vehicles are built and medical care is delivered. As technology continues to advance, Best Precision, a leading Plastic molds manufacturer plays an even more critical role in shaping the future of these industries, driving advancements that benefit both consumers and patients alike.