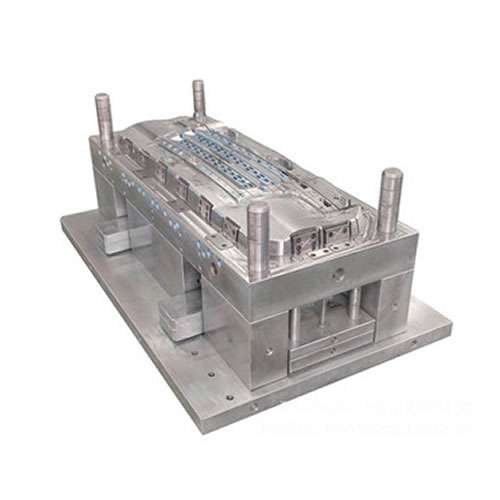

Plastic injection moulding

Plastic injection moulding is an amazingly significant piece of various enterprises and understanding the injection mold shaping cycle may help shed some light on its significance in present-day ventures. By knowing how it functions, you will find out what you ought to expect when you next submit a request as to accuracy in shaping favorable circumstances. Fundamentally, Moulding is about the creation of parts, lodgings, and sections utilizing a profoundly exact framing interaction and gadget. Such an interaction regularly utilizes a select kind of polymer shape to make the vital plastic part. Notwithstanding, composite materials and even metal are some of the time used too.

Why choose plastic injection moulding?

The primary concern of moulding is to create plastic parts that are of tight dimensional resilience. Liquid plastic pellets called the soften, are injected into the shape, cooled, and shot out from the form depressions. What makes this specific interaction unique is the accuracy level with which it can make plastic parts everywhere in volumes and at low expenses. However long the actual form is made and the interaction boundaries are steady and repeatable during the moulding cycle, the part will come out precisely on a case-by-case basis. The interaction is genuinely quick, too, so large-scale manufacturing should be possible rapidly. At Best Precision Tools, we can oblige requests of any size and timetable for plastic-injected parts without much of a stretch. The motivation behind the exactness of Plastic injection moulding is to make accurate plastic parts effectively where the liquefied plastic shapes are injected into molds made of steel. Doing so will top off the entirety of the accessible space in the form pits and when the shape closes, it will chill off and assume the state of the part should have been consequently launched out from the injection moulding form.

Injection moulding permits makers to create huge amounts of plastic parts in a quick, proficient, and practical way. This interaction infuses liquid plastic into firm molds or edges and afterward applies pressure as the plastic cools. Utilizing this procedure, Plastic components manufacturer appreciate a serious level of plan adaptability and can make portions of practically any size, shape, or capacity. This interaction can likewise assemble complex plans with numerous many-sided components. beyond its adaptability and proficiency, injection moulding offers makers various significant benefits by lessening costs just as the ecological effect of creation.

Injection moulding is an incredibly flexible technique for creating parts and items. It is one of the favored techniques for assembling parts since it has numerous benefits over different strategies for Plastic injection moulding. Not exclusively is precision moulding more dependable, but it is likewise incredibly proficient.

As a leading injection molds manufacturer, Best Precision Tools offer mouldings for makers of food items, shopper products, bundling, and machines. Our cycles permit organizations to deliver any amount of plastic parts to their accurate details while bringing about lower financial and worldly speculations than those needed by other assembling measures.

Notwithstanding injection moulding, we offer an assortment of blow-forming, machining, underlying frothing, and thermoforming administrations. Reach us to figure out how the Best precision tools can assist with your organization’s next project.

Injection moulding offers numerous advantages over different kinds of plastic assembling measures. Some of these include:

- Cost-effectiveness

- Short cycles

- Higher quality

FAQ's

Plastic injection molding is a sort of moulding that is the most costly and refined cycle of shape plan on the lookout. It is just utilized in the assembling interaction in little and rare events when item advancement requires an uncommonly exact type of plstic injection molding.

An assortment of parts can be made by plastic injection moulding Models are auto segments, for example, intake manifolds, dashboard switches and handles; clinical parts like needles or careful gadgets; machine lodgings, electrical circuit sheets, bottle covers, toys, gem boxes and segments of versatile potties.

Plastic injection moulding is a technique to get shaped items by infusing plastic materials liquid by heat into a mold, and afterward cooling and cementing them. The technique is appropriate for the large-scale manufacturing of items with confounded shapes, and takes an enormous part in the space of plastic preparation.

The plastic injection moulding cycle includes warming and infusing plastic material under pressure into a shut metal mould. The liquid plastic cools and solidifies into the shape inside the mold apparatus, which at that point opens to permit the moldings to be shot out or taken out for review, conveyance or optional tasks.

Plastic injection molding is an assembling cycle for creating parts in enormous volumes. It is most ordinarily utilized in large scale manufacturing measures where a similar part is being made thousands or even great many occasions in progression.

Advantages of plastic injection moulding

- * Fast creation and profoundly effective. Injection moulding can create a fantastic measure of parts each hour.

- * Plan adaptability.

- * High-output creation.

- * Huge material decision.

- * Low piece rates.