Best Practices for extending injection molds lifespan

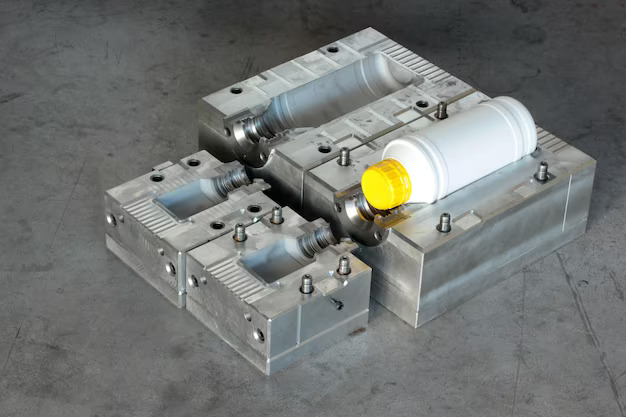

What is known as mold life?

Mold life refers to the duration or lifespan an injection mold can effectively produce quality parts before it requires repair, maintenance, or replacement. Understanding mold life and the factors that influence it is crucial for optimizing production processes and managing costs effectively.

Factors that influence the injection mold

Several key factors determine the mold life of injection molds. First and foremost is the material used for the mold itself.

Other factors influencing mold life include the design of the mold, proper maintenance practices, and the operating conditions during production. A well-designed mold with proper cooling channels, sufficient draft angles, and appropriate gating can help distribute heat evenly and minimize stress on the mold, thus prolonging its lifespan. Regular maintenance, including cleaning, inspection, and lubrication, is essential for preventing damage and addressing issues promptly.

Additionally, proper handling, storage, and protection from contaminants can also contribute to extending mold life.

Let us get into the details of the best practices required to increase the lifespan of injection molds.

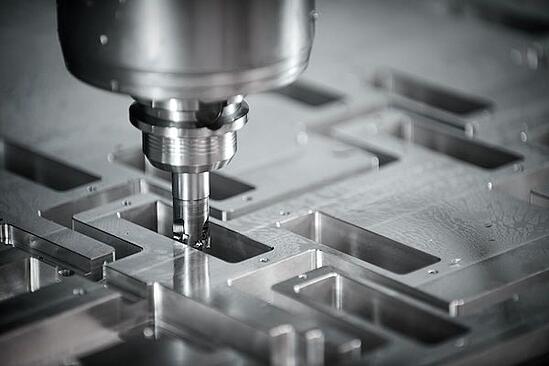

Material Selection

Injection molds manufacturer should use appropriate materials for mold to improve its lifespan. Choosing high-quality materials with excellent heat resistance, durability, and resistance to wear can without a doubt extend the lifespan of your molds. Materials such as hardened steel, stainless steel, and aluminum alloys are commonly used in injection molds due to their superior properties. Understanding the specific requirements of your molding project and consulting with experts in the field can help you make informed decisions about material selection, leading to longer-lasting molds and improved overall productivity.

Proper Maintenance Techniques

Implementing proper maintenance techniques by injection molds manufacturer is essential for increasing the lifespan of injection molds. Regular cleaning and inspection are vital to identifying and addressing any potential issues without fail. Cleaning molds after each production run helps prevent the accumulation of debris, contaminants, and residues that can lead to corrosion or damage over time. Inspecting molds for signs of wear, cracks, or defects allows for early detection and timely repairs. Additionally, applying appropriate lubrication and corrosion-resistant coatings can provide added protection, ensuring optimal performance and an extended mold lifespan.

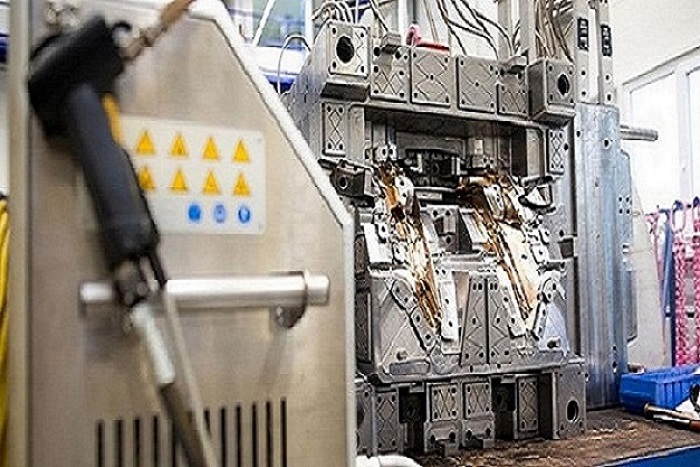

Cooling System Optimisation

Inadequate cooling can result in thermal stresses, warping, and premature wear of the mold. Optimizing the cooling system involves factors such as proper water flow rate, temperature control, and placement of cooling channels. Regular monitoring of cooling system performance and maintenance of cooling channels is essential to ensure consistent cooling and prevent potential issues that may compromise mold lifespan.

Regular Cleaning and Inspection

By addressing any signs of wear, cracks, or damage issues promptly through repairs or maintenance, you can prevent further deterioration and extend the overall lifespan of the mold. Implementing a proactive cleaning and inspection schedule ensures injection molds manufacturer that molds remain in optimal condition for extended periods and increase the lifespan of the molds.

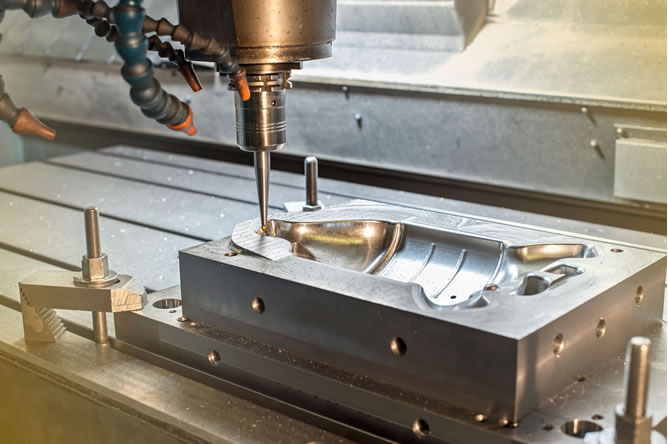

Mold Design Considerations

Factors such as wall thickness, draft angles, parting lines, and gate design can significantly impact the stress and wear experienced by injection molds. Optimal wall thickness ensures structural integrity, while appropriate draft angles facilitate smooth ejection of parts, reducing stress on the mold. By considering the essential design factors and working closely with experienced mold designers, you can create molds with an extended lifespan.

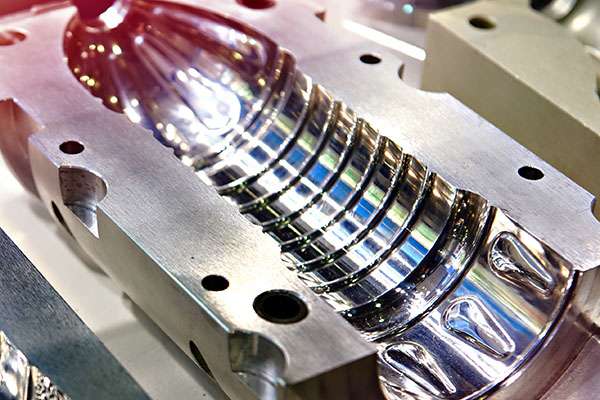

Surface Treatment Methods

Applying effective surface treatment methods is a valuable technique for enhancing mold resistance and longevity. Various surface treatments, such as nitriding, chrome plating, or PVD coatings, can significantly improve the mold’s resistance to wear, corrosion, and sticking. Nitriding creates a hard and wear-resistant surface layer, while chrome plating offers excellent corrosion resistance. PVD coatings provide enhanced release properties, reducing the likelihood of part sticking and improving mold lifespan. By selecting the appropriate surface treatment method based on your specific molding requirements, you can enhance the durability and lifespan of your molds.

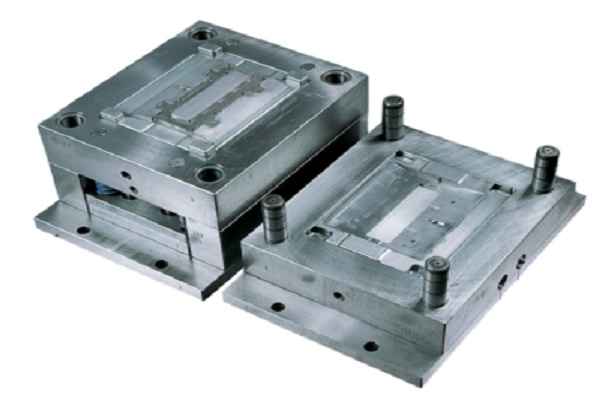

Mold Storage and Handling

When not in use, molds should be stored in a clean, dry, and temperature-controlled environment to prevent corrosion and damage. It is crucial to protect molds from dust, moisture, and any potential impact that could reduce the lifespan of the mold. Handling plastic molds carefully, using appropriate lifting equipment, and avoiding unnecessary stress or mishandling can prevent damage and ensure their longevity.

Mold Repair and Restoration

When molds become damaged or show signs of wear, timely repair and restoration can be effective strategies for extending their lifespan. Depending on the severity of the damage, repair techniques such as welding, machining, or polishing may be employed. Additionally, restoring worn-out or damaged surface coatings through reapplication or reconditioning can help improve mold performance and durability. Doing these will most definitely increase the lifespan of mold.

The lifespan of molds depends on various factors like the material used, the type of plastic being injected, the mold design, maintenance practices, and operating conditions by the injection molds manufacturer. By carefully considering these factors and implementing best practices, manufacturers can extend the lifespan of their molds, reduce downtime, and achieve consistent production quality.

By proactively managing mold life, a plastic moulding parts manufacturer can enhance productivity, minimize mold repair or replacement costs and maintain high-quality production. Investing time and effort in understanding and implementing best practices for mold lifespan optimization injection molds manufacturer can lead to significant benefits in the long run.