The Vital Role of Molds Manufacturer in the Plastic Manufacturing Industry

In the vast field of the manufacturing industry, the creation of plastic products stands out as a cornerstone of modern living. From intricate components in electronics to everyday household items, plastics have revolutionized our world. However, behind the scenes of this innovation lies a crucial player: molds manufacturer. These unsung heroes play an important role in shaping the plastic manufacturing industry, enabling the production of diverse and intricate plastic products that have become an integral part of our lives. Everyone must still be confused about the role the mold producer has in our day-to-day lives. To get a better idea of this aspect, let us get into the significant role of molds manufacturer in plastic manufacturing, exploring their expertise, techniques, and impact on various sectors.

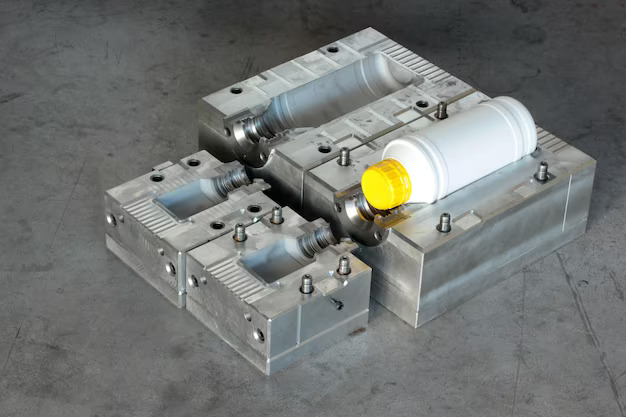

The Backbone of Plastic Manufacturing: Molds

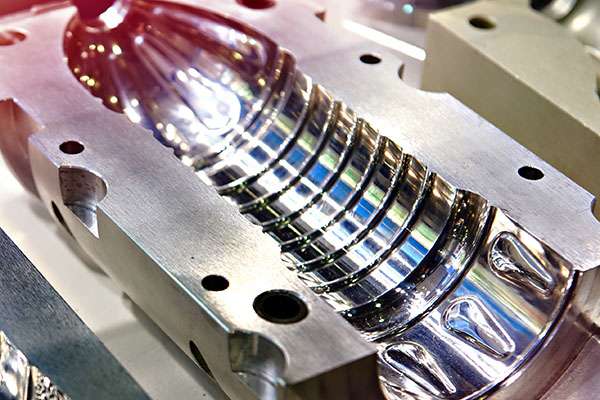

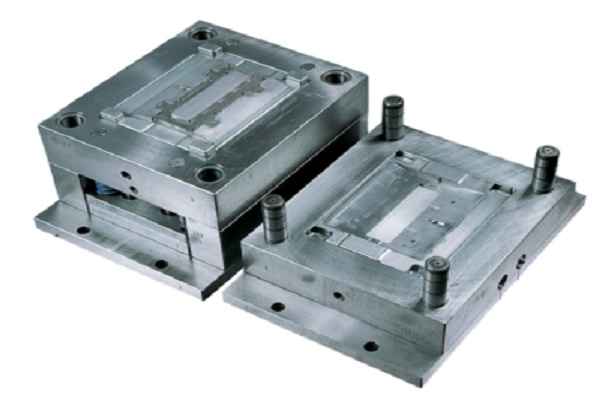

At the heart of the plastic manufacturing process lies the creation of molds. A mold is a precise and intricate tool that determines the shape, size, and details of the final plastic product. Molds are designed to be reusable, allowing for efficient mass production of consistent items.

Expertise in Design and Engineering

Molds producers are responsible for translating a concept into an actual mold that accurately reflects the desired product. This requires a deep understanding of design principles, engineering, and materials science. Mold designers meticulously analyze product specifications, considering factors such as material properties, functionality, and aesthetics. Their expertise ensures that the mold can withstand the pressures, temperatures, and stresses of the manufacturing process.

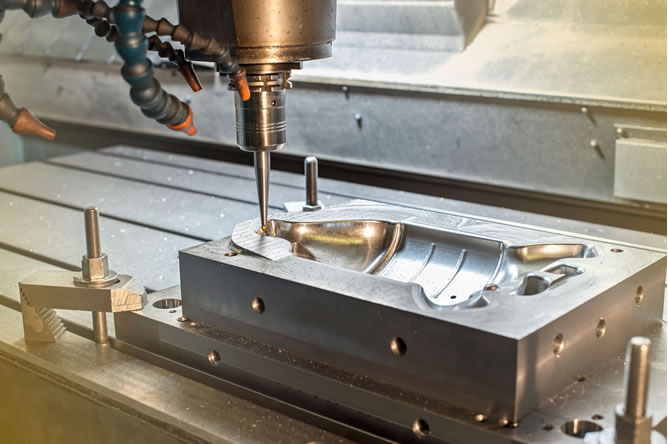

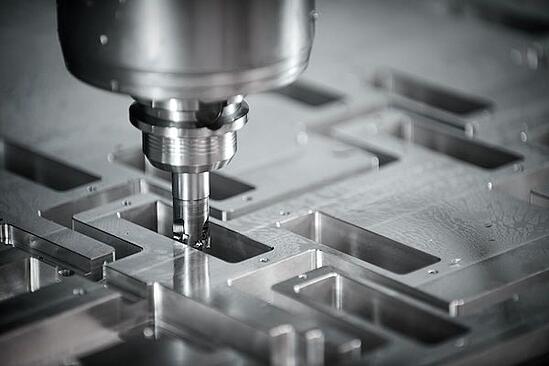

Precision in Manufacturing

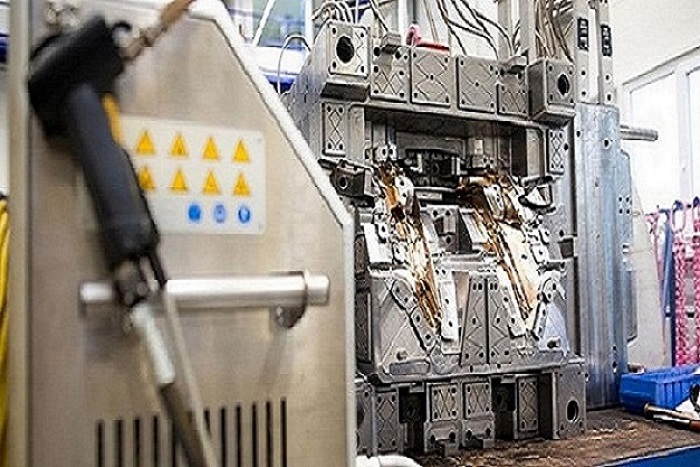

The creation of molds is a meticulous process that demands precision and attention to detail. Advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) are crucial in translating intricate designs into tangible molds. CNC (Computer Numerical Control) machining is often employed to fabricate molds with utmost accuracy. The precision achieved in mold manufacturing directly impacts the quality and consistency of the plastic products produced.

Versatility in Product Range

Molds manufacturer cater to a wide array of industries, each with unique demands. From automotive parts to medical devices, consumer electronics to packaging, the versatility of mold manufacturing allows for the production of an extensive range of plastic products. This adaptability showcases the mastery of mold producers in understanding the specific requirements of each sector.

Innovation and Material Compatibility

As technology advances and new materials emerge, mold producers play a critical role in innovating to accommodate these changes. They must understand the compatibility of different plastics with various mold materials, ensuring that the production process remains efficient and that the final products meet quality standards.

Streamlining Production Processes

Efficiency is paramount in modern manufacturing. Molds manufacturer continually explore ways to streamline the production process, reduce waste, and enhance productivity. By optimizing mold designs, incorporating innovative cooling systems, and employing automation, they contribute to cost-effective and environmentally responsible manufacturing practices.

Collaboration in the Industry

Mold makers are not isolated entities; they often collaborate closely with plastic manufacturers, product designers, engineers, and quality control experts. This collaborative approach ensures that the mold meets the specific requirements of the product and that any potential issues are addressed early in the design phase. The combination between these stakeholders results in a smoother production process and higher-quality end products.

Economic Impact and Employment

The role of molds manufacturer extends beyond technical expertise. They contribute significantly to the economy by generating employment opportunities and fostering a skilled workforce. Moreover, the plastic products they help create drive various industries, generating revenue and supporting economic growth.

Best Precision significantly influences the economy and employment landscape. By producing molds essential for various industries like automotive, electronics, and consumer goods, it drives innovation and production efficiency. This, in turn, fuels economic growth by supporting downstream manufacturing. Additionally, Best Precision generates jobs across the design, engineering, production, and maintenance sectors, enhancing local employment opportunities. Its contribution can be seen through the supply chain, promoting economic development while providing skilled and unskilled labor opportunities, thus playing a vital role in shaping a robust economy and job market.

The plastic products we encounter daily are the result of a remarkable synergy between various elements of the manufacturing process. Among these elements, mold makers stand as key players, shaping the way we interact with technology, healthcare, consumer goods, and more. Their expertise, precision, adaptability, and commitment to innovation ensure that the plastic injection moulding manufacturing industry remains dynamic and relevant in an ever-changing world. As we continue to rely on plastic products for convenience, safety, and progress, let us remember the vital role that molds manufacturer play in shaping the way we live, work, and connect.