Factors to Consider When Selecting an Injection Molds Manufacturer

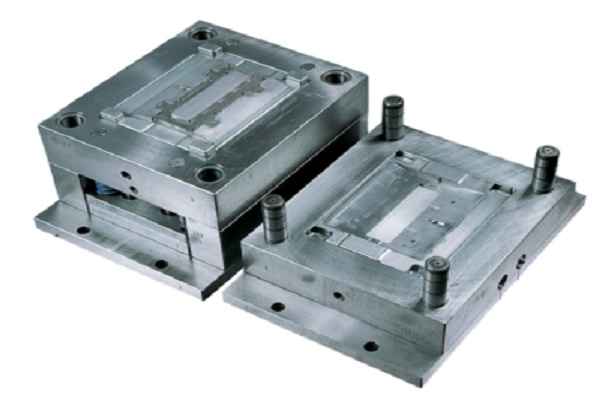

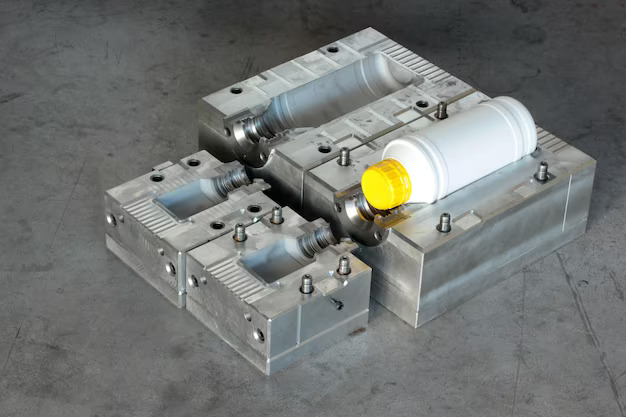

When it comes to manufacturing processes, the use of injection molds plays a very important role in producing high-quality parts and products. Selecting the right injection molds manufacturer is a crucial decision that can significantly impact the efficiency, cost-effectiveness, and overall success of your production. There are a few important factors to consider before selecting an Injection Molds Manufacturer to make sure that you get the most out of your money.

The manufacturer that you select for crafting your injection molds plays a very important role in the success of your production journey. Their expertise, precision, and commitment directly influence the quality, timeline, and overall efficiency of your manufacturing process. Opting for the right partner thus becomes a vital decision with far-reaching implications for your project’s success.

Understanding Your Requirements:

Before initiating your search for a manufacturer, define your project requirements thoroughly. Consider the type of mold needed, material specifications, part complexity, expected production volume, and any specific features or finishing required. This clarity will serve as a guideline during discussions with potential manufacturers and help in finding the most suitable partner for your project.

Experience and Expertise:

An injection molds manufacturer with extensive experience brings valuable insights and a refined skill set to the table. Look for companies that have a proven track record in your industry or with similar projects. Evaluate their portfolio, client testimonials, and case studies, and inquire about their experience in handling diverse materials and complex designs. A seasoned manufacturer is better equipped to anticipate challenges and offer effective solutions.

Quality Standards and Certifications:

Assess the manufacturer’s commitment to quality by examining their adherence to industry standards and certifications. Certifications like ISO 9001 demonstrate their dedication to maintaining consistent quality in their processes. Additionally, inquire about their quality control procedures, inspection protocols, and measures taken to ensure that each mold meets the specified standards.

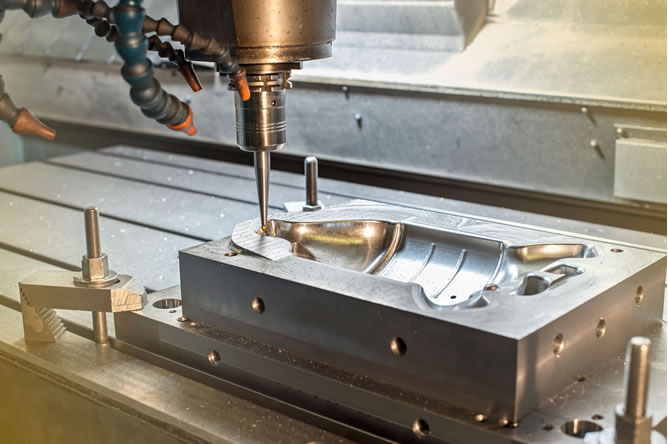

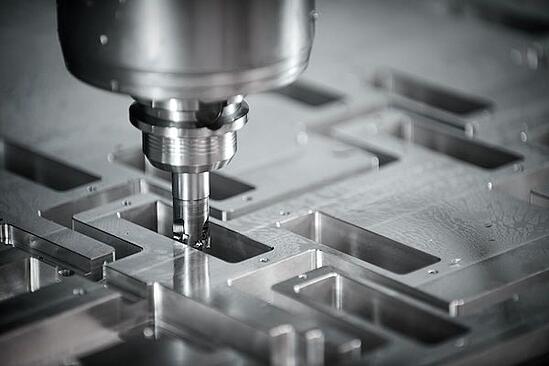

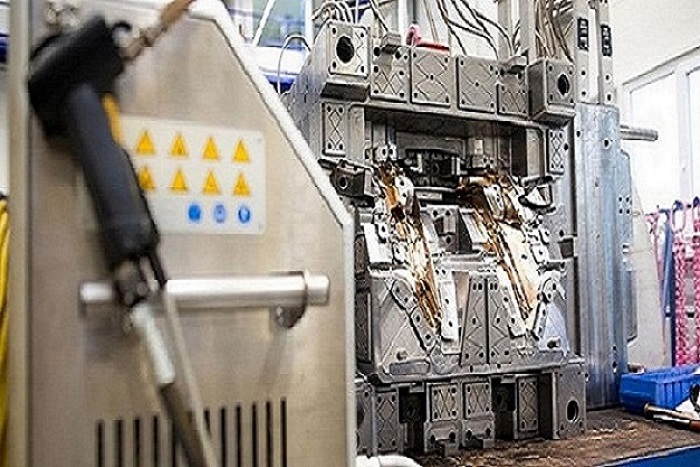

Technology and Equipment:

Advanced technology and cutting-edge equipment significantly influence the quality and efficiency of mold production. Inquire about the manufacturing processes employed by the manufacturer, the types of machinery they use, and their investment in innovative technologies. Injection Molds Manufacturer embracing newer technologies often deliver higher precision, faster production times, and improved overall quality.

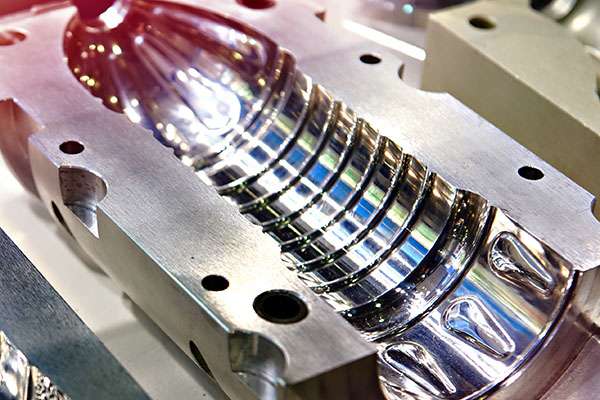

Customization and Design Capabilities:

The ability to customize molds according to specific project requirements is invaluable. Evaluate the manufacturer’s design capabilities, expertise in creating intricate molds, and willingness to collaborate on customization. A manufacturer offering design assistance, prototyping services, and iterative improvements can streamline the development process and lead to optimal mold designs.

Material Selection and Compatibility:

Different materials offer varying properties and are suited for specific applications. Ensure that the manufacturer has expertise in working with the materials required for your project. Ask for examples of similar materials they’ve handled and inquire about their knowledge regarding material compatibility, durability, and performance in different environments.

Cost and Pricing Structure:

While cost is a significant factor, it should be evaluated in conjunction with the overall value offered. Obtain detailed quotes from multiple manufacturers, including not only the initial costs but also additional expenses like tooling, revisions, maintenance, and shipping. Strive to strike a balance between affordability and quality to ensure a cost-effective yet reliable partnership.

Lead Times and Production Capacity:

Timely production and delivery schedules are crucial for project timelines and market competitiveness. Inquire about the manufacturer’s lead times, production capacity, and flexibility to accommodate fluctuations in demand. A manufacturer with streamlined processes, efficient scheduling, and contingency plans for unforeseen circumstances can ensure consistent supply without compromising quality.

Reputation and Reviews:

Research the manufacturer’s reputation within the industry by seeking testimonials, reviews, and case studies from previous clients. Consider factors such as reliability, consistency in delivering on promises, and overall client satisfaction. Identify any patterns in feedback that might influence your decision positively or negatively.

Communication and Customer Support:

Effective communication is the cornerstone of a successful partnership. Evaluate the manufacturer’s communication practices, responsiveness to inquiries, and willingness to provide ongoing support. An Injection Molds Manufacturer who values transparent communication keeps you updated on project milestones and offers reliable customer support can contribute significantly to a smooth and productive collaboration.

Selecting the right Plastic injection moulding involves a comprehensive evaluation of various factors to ensure a fruitful partnership. By considering aspects such as experience, quality standards, technology, customization, cost, and communication, you can make an informed decision that aligns with your specific production needs. Prioritize thorough research and due diligence to forge a long-term partnership that fosters quality, efficiency, and mutual growth.